Brief Function Introduction:

The KUKA KR150-2 F2000 robotic arm is a high-performance, versatile solution designed for precision assembly and handling tasks in various industries, including automotive, electronics, and logistics. Its advanced capabilities ensure efficient, accurate movements and are tailored to meet the demands of automation in manufacturing processes.

Product Specifications:

| Operating Range: | Up to 1500 mm |

| Maximum Load Capacity: | 20 kg |

| Repeatability: | ±0.01 mm |

| Speed (Max): | 2500 mm/s |

| Travel Speed (Welding): | 1200 mm/s |

| Joints: | 6-axis |

| Communication Protocol: | EtherCAT |

| Control System: | KUKA.Kinetic |

| Environment: | IP65 |

| Power Consumption: | 1.5 kW |

| Electrical Supply: | Single phase, 230 V AC |

| Weight: | 145 kg |

| Maintenance Interval: | Every 5 years or 50,000 hours of operation |

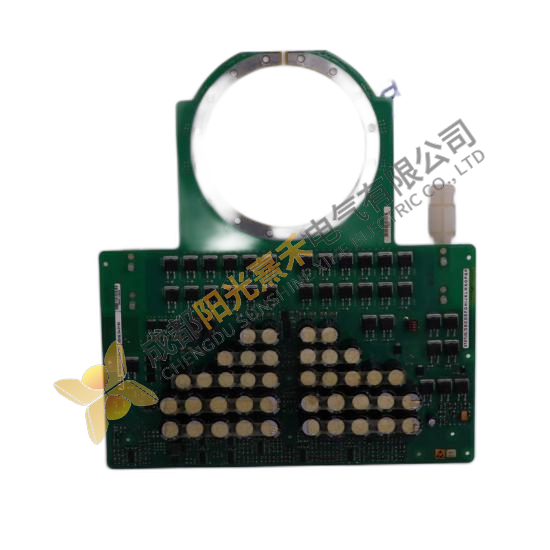

Product Details:

The KUKA KR150-2 F2000 robotic arm is meticulously engineered for unparalleled performance and durability. Its compact yet powerful design allows for precise manipulation and assembly, making it an indispensable tool in modern manufacturing lines.

With its advanced 6-axis articulation, this robotic arm offers exceptional flexibility and maneuverability, capable of navigating complex workspaces with ease. It's equipped with KUKA's proprietary control system, KUKA.Kinetic, ensuring smooth, reliable operation.

Featuring a high repeatability of ±0.01 mm, the KUKA KR150-2 F2000 guarantees consistent quality in every production cycle, minimizing errors and maximizing efficiency. The inclusion of EtherCAT communication protocol facilitates seamless integration with existing factory systems, enhancing productivity.

Designed with robustness in mind, this robotic arm withstands challenging industrial environments, thanks to its IP65-rated enclosure. This protection ensures operational reliability even under dusty or wet conditions, making it suitable for a wide range of applications.

For maintenance, the KUKA KR150-2 F2000 boasts a long service life with a recommended inspection every 5 years or after 50,000 hours of use. This proactive approach minimizes downtime and keeps the robotic arm in optimal condition, ensuring continuous high-quality output.

Notice:

Discover a vast range of automation and control components from top-tier OEMs in our inventory. Missed what you're after? Reach out—many more items await off-shelf.

Note: In case of discrepancies between displayed pictures and product models, the model description prevails. Request custom product images; we'll promptly arrange warehouse snapshots for your verification.

Got unique requirements? Let's talk. Timely responses guaranteed.